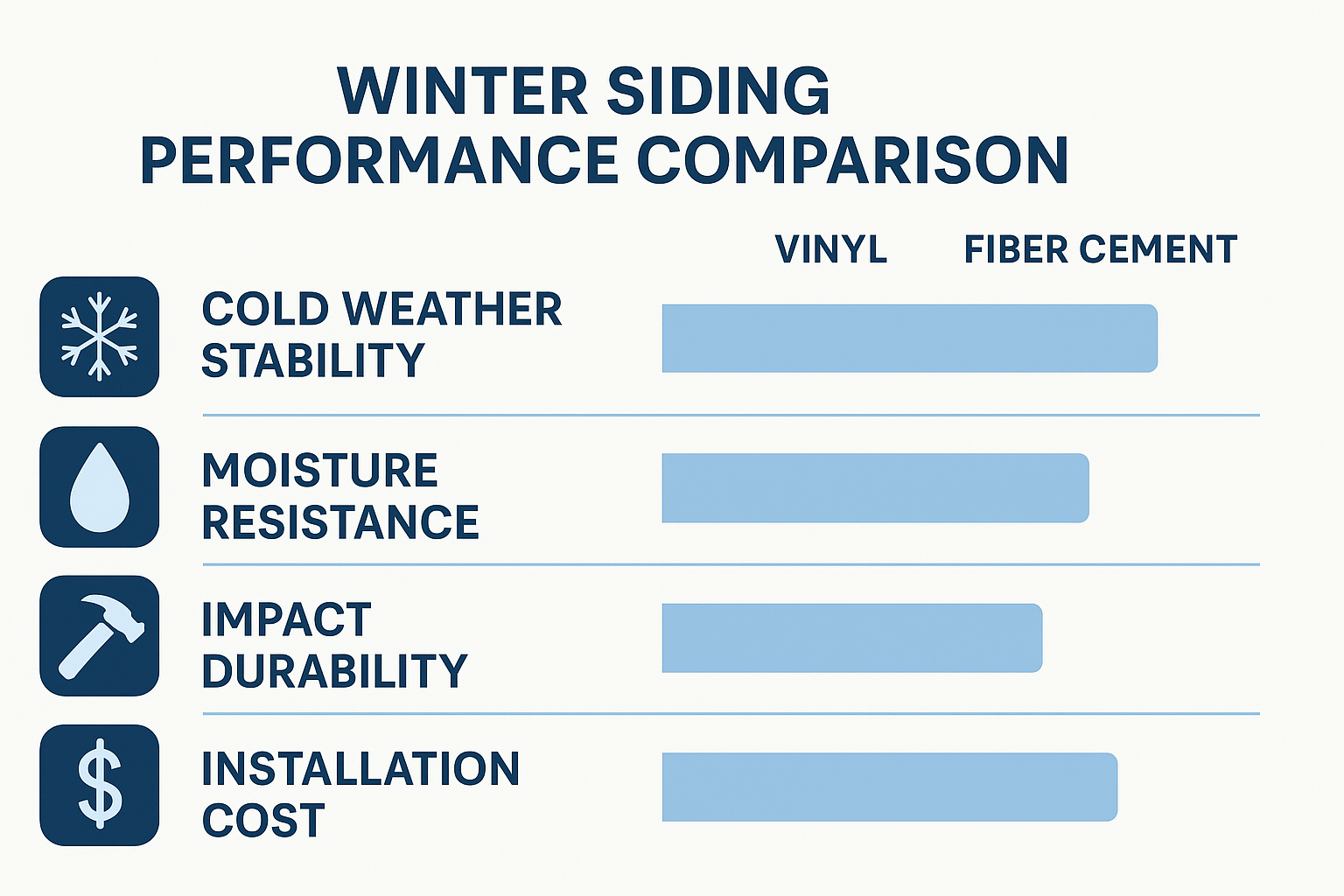

For Canadian winters, fiber cement siding outperforms vinyl in durability and stability, while vinyl offers better value and easier installation. Both materials handle extreme cold, but their performance differs significantly in freeze-thaw cycles, moisture resistance, and long-term maintenance needs.

This detailed comparison examines how vinyl and fiber cement siding perform in Canadian winter conditions. You'll discover real performance data, cost analysis, and expert recommendations based on your specific climate zone.

For Canadian winters, fiber cement siding outperforms vinyl in durability and stability, while vinyl offers better value and easier installation. Both materials handle extreme cold, but their performance differs significantly in freeze-thaw cycles, moisture resistance, and long-term maintenance needs.

This detailed comparison examines how vinyl and fiber cement siding perform in Canadian winter conditions. You'll discover real performance data, cost analysis, and expert recommendations based on your specific climate zone.

📊 Cost Breakdown

Project Component

Average Cost

% of Total

Materials

$5,000 - $8,000

50-60%

Labor

$3,000 - $5,000

30-35%

Permits & Disposal

$500 - $1,000

5-10%

Total Project

$8,500 - $14,000

100%

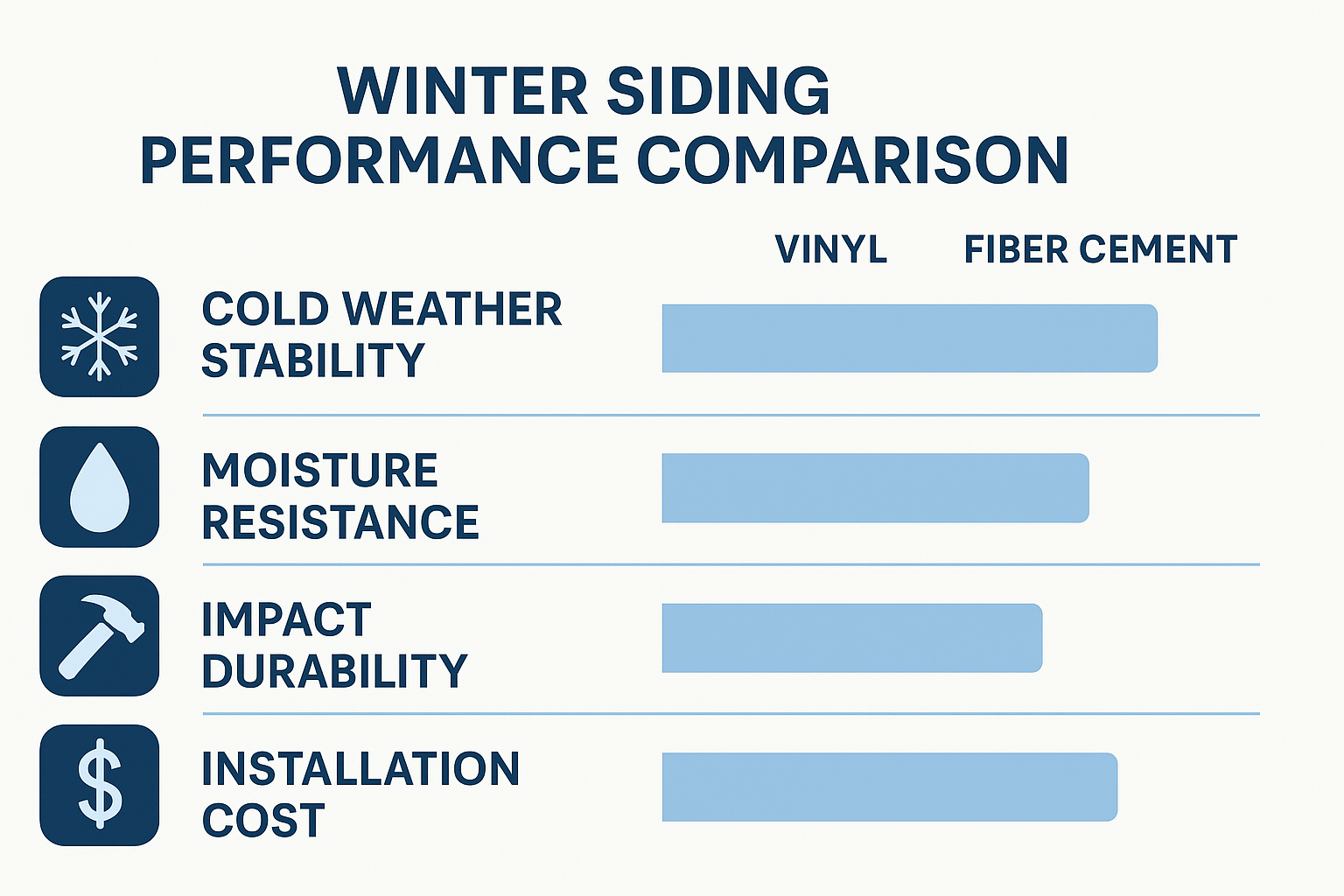

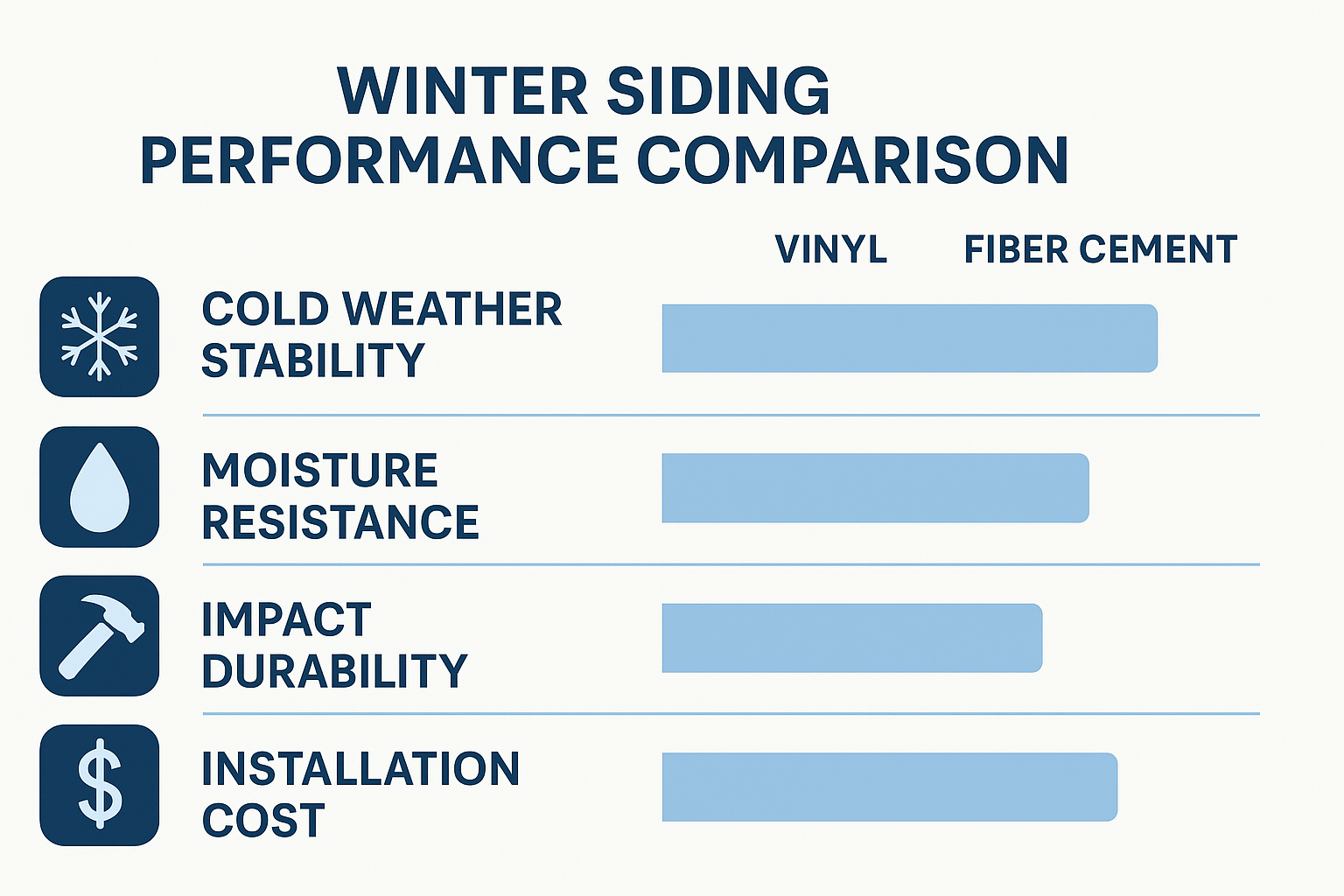

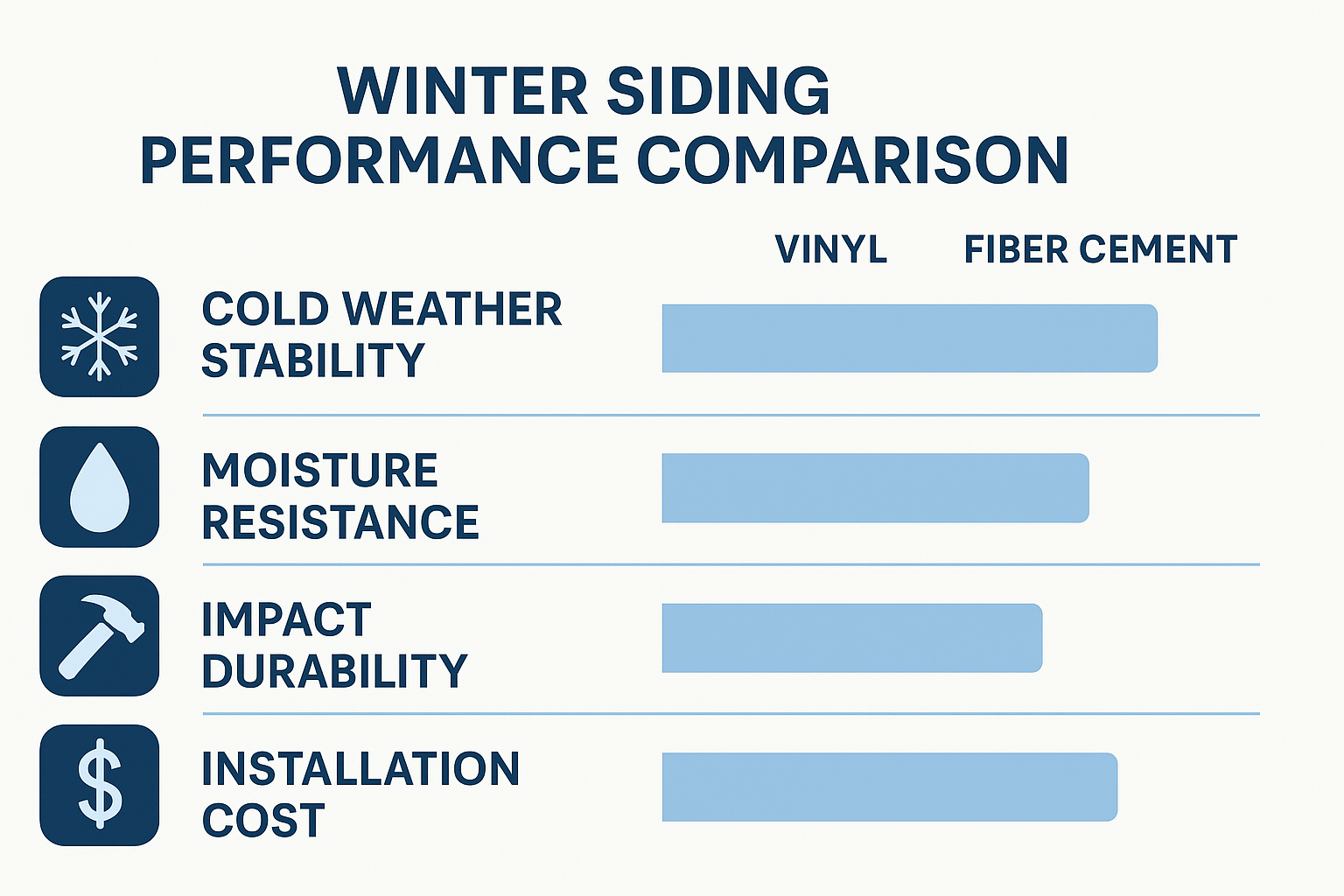

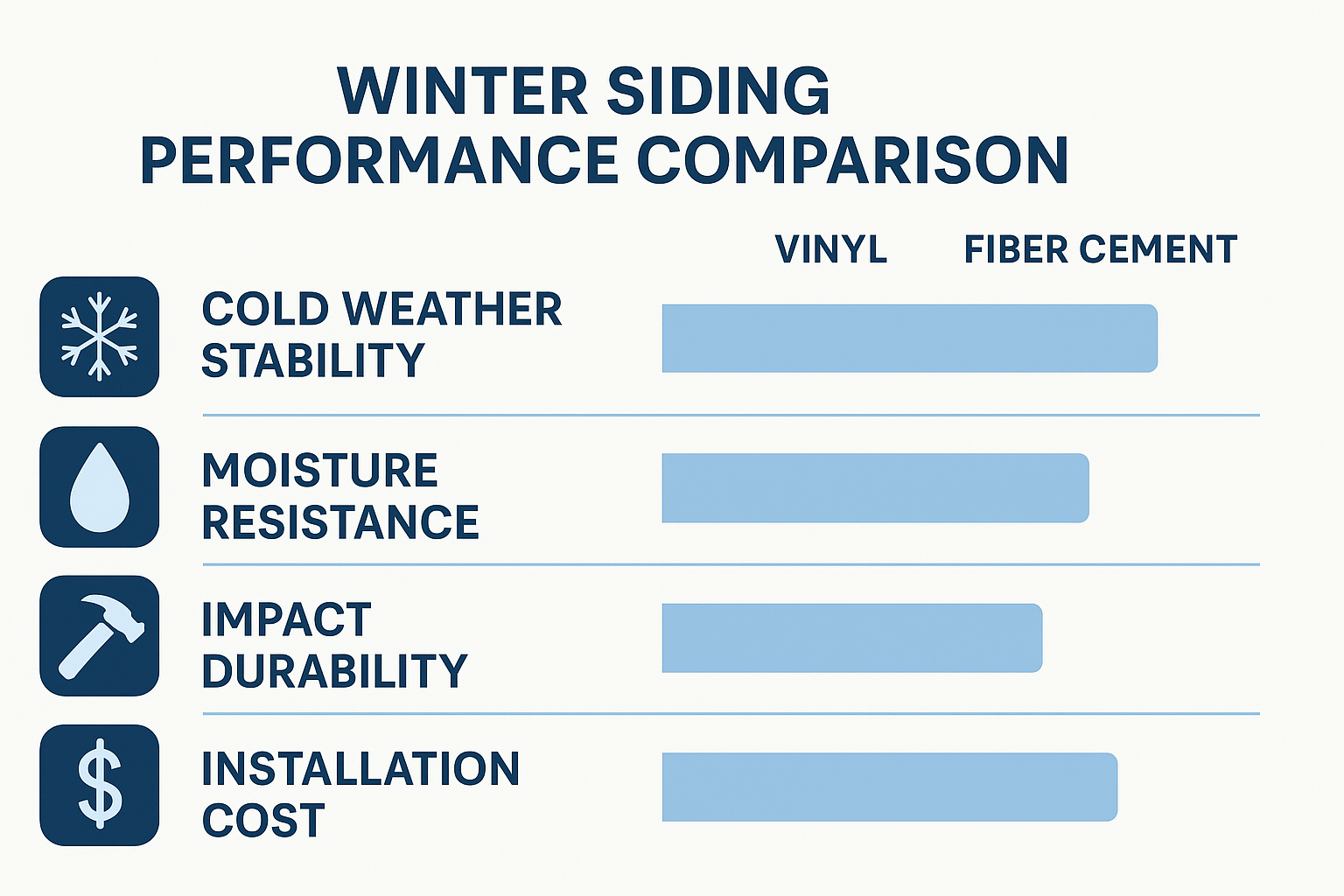

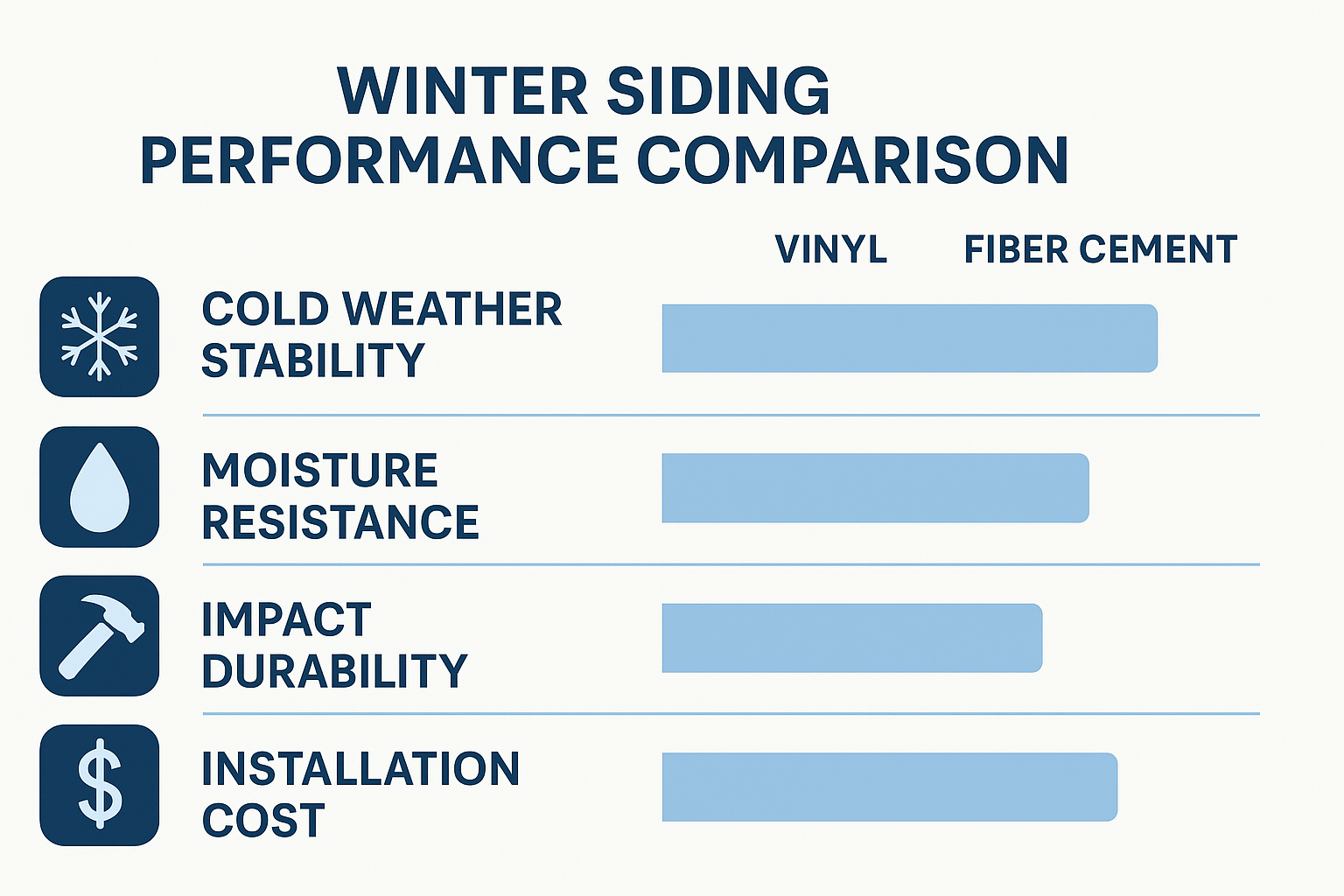

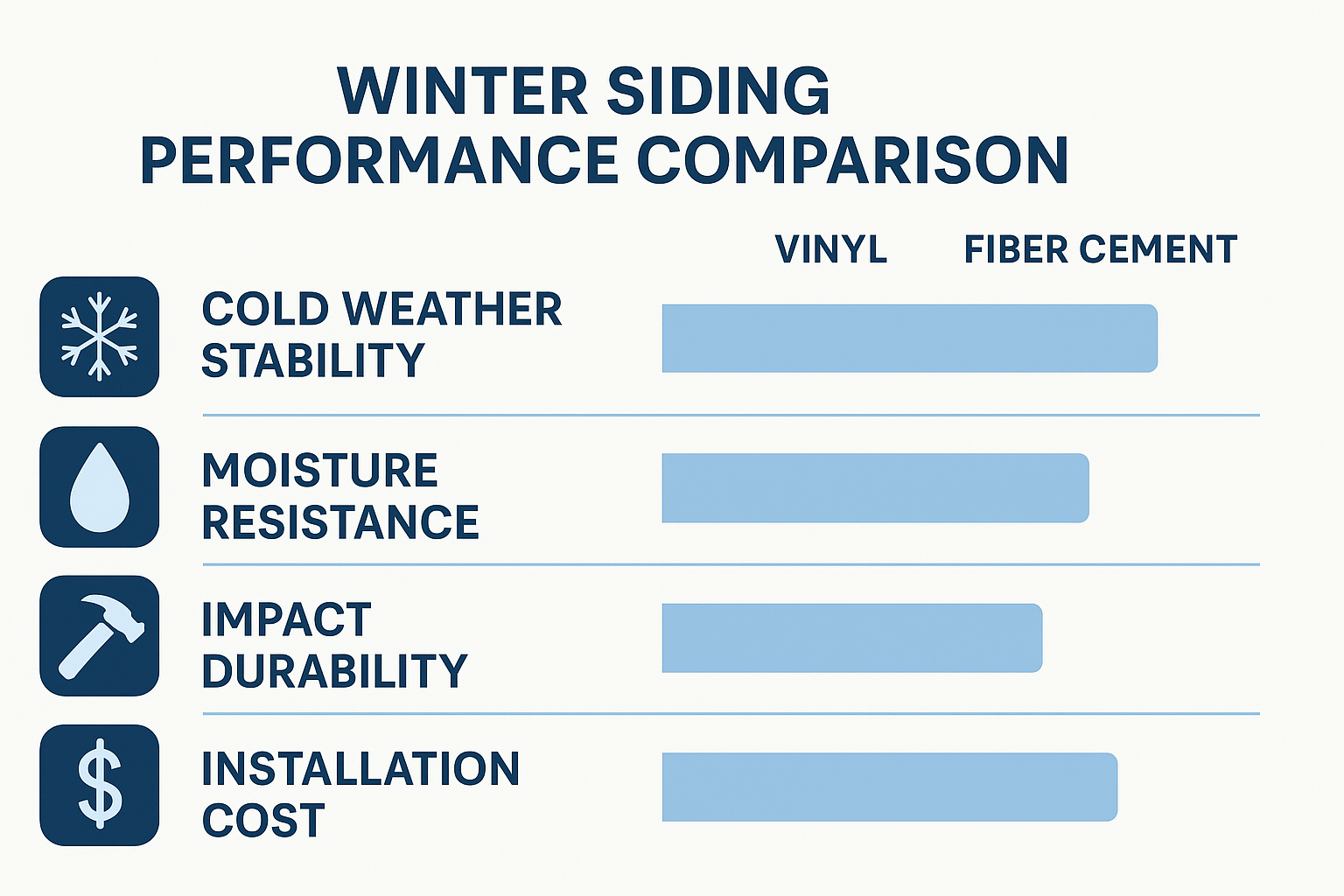

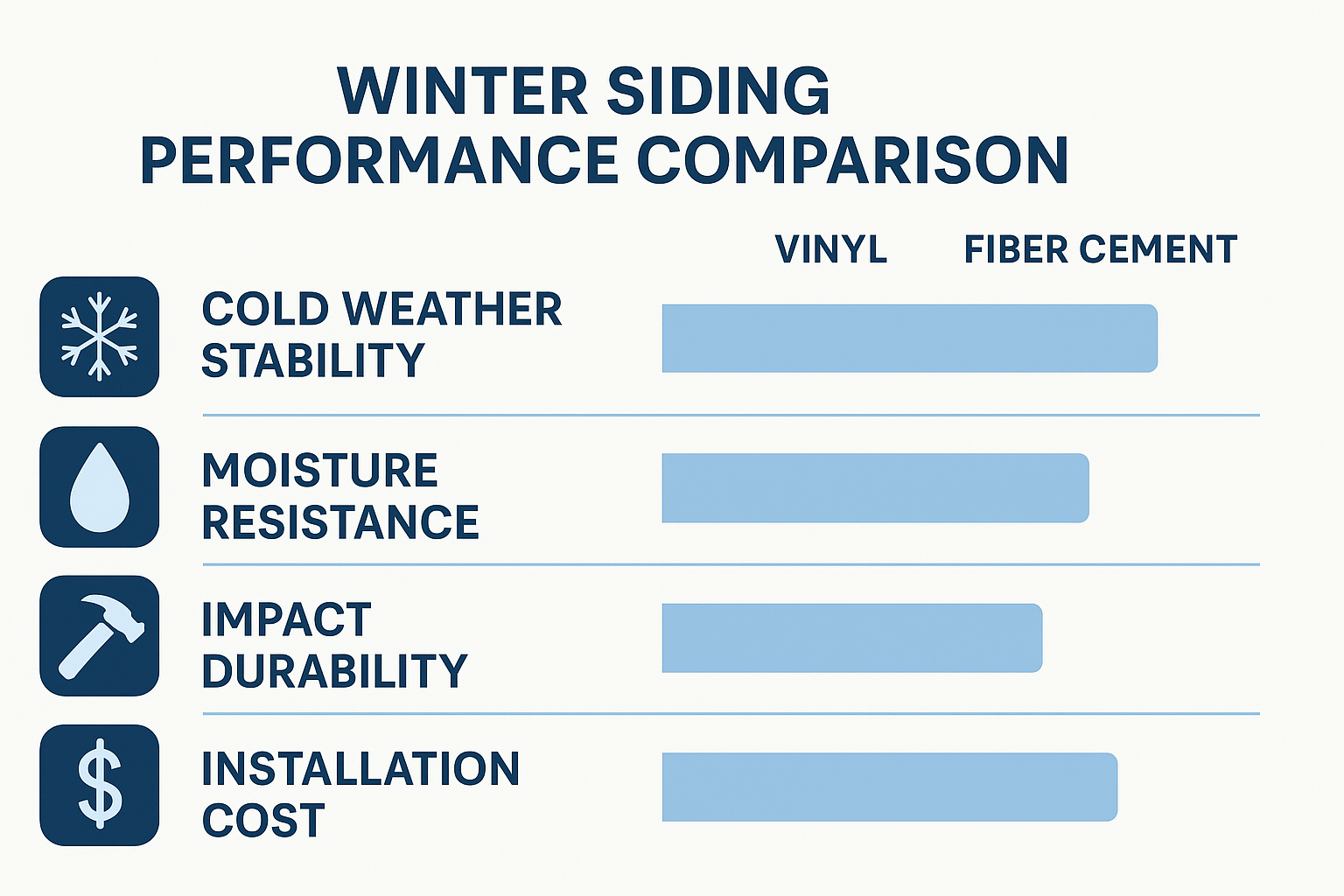

Vinyl vs. Fiber Cement: Canadian Winter Performance Analysis

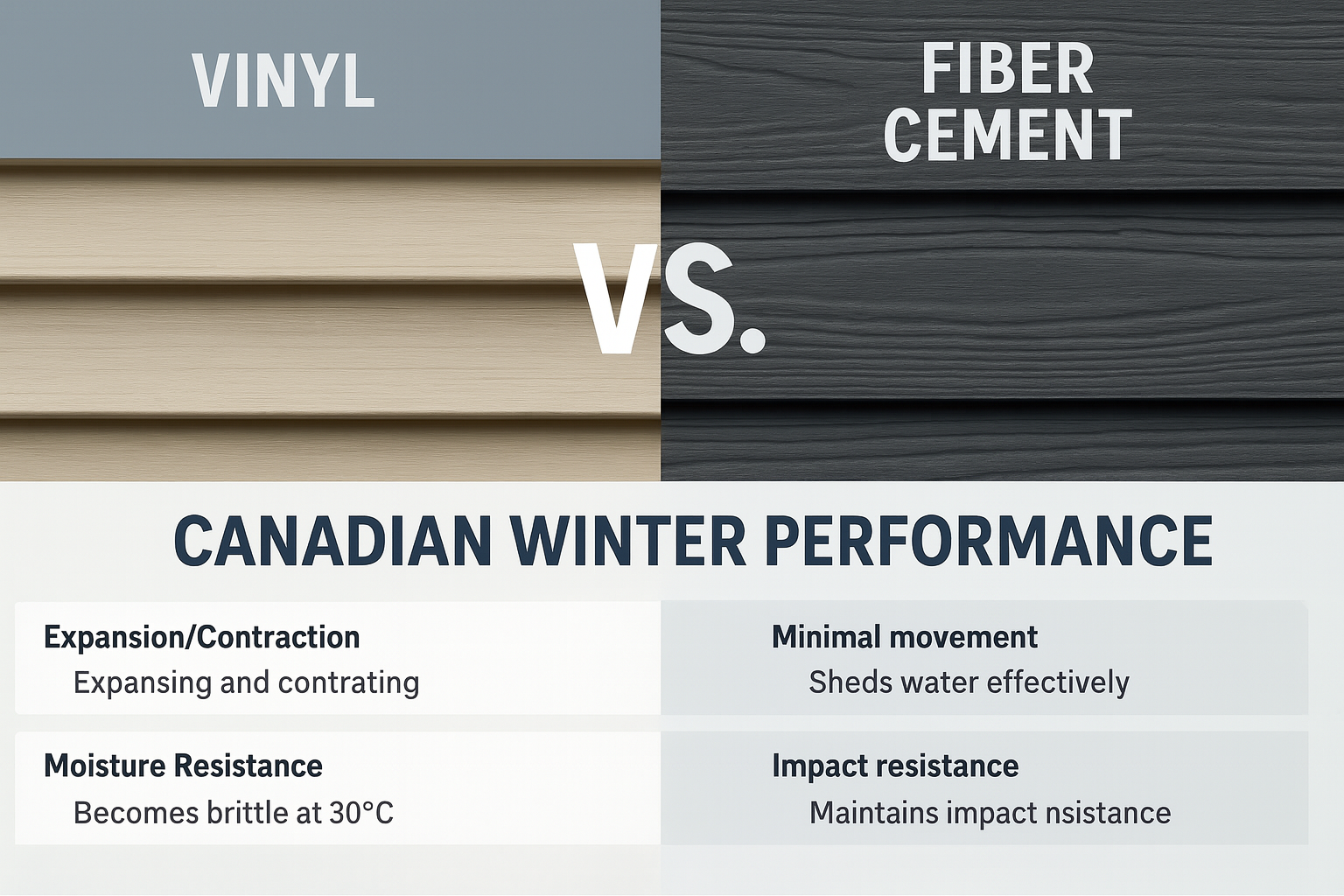

Canadian winters test siding materials with temperature swings from -40°C to +5°C, sometimes within days. Ice formation, snow load, and freeze-thaw cycles challenge material integrity. Understanding how vinyl and fiber cement respond to these conditions guides your selection.

Quick comparison overview:

Vinyl Siding: Expands/contracts significantly, lower cost, easier installation.

Fiber Cement: Minimal movement, higher cost, professional installation required.

Durability Winner: Fiber cement lasts 50+ years vs vinyl's 20-30 years.

Cost Winner: Vinyl costs 40-50% less installed.

Maintenance Winner: Vinyl needs less frequent maintenance.

📊 Siding Material Comparison

Siding Type

Durability

Maintenance

Cost Range

Vinyl Siding

⭐⭐⭐⭐

Low

$3-$8/sq ft

Fiber Cement

⭐⭐⭐⭐⭐

Low-Medium

$6-$12/sq ft

Wood Siding

⭐⭐⭐

High

$8-$15/sq ft

Metal Siding

⭐⭐⭐⭐⭐

Very Low

$7-$16/sq ft

📊 Maintenance Schedule

Frequency

Task

Importance

Monthly

Visual inspection

Medium

Quarterly

Clean gutters & downspouts

High

Bi-Annually

Professional inspection

High

Annually

Deep cleaning & repairs

Medium

1. Cold Weather Expansion and Contraction Rates

Vinyl siding expands and contracts dramatically with temperature changes. A 12-foot vinyl panel can change length by 1.3cm between summer and winter extremes. This movement requires proper installation with expansion gaps. Improper installation causes buckling, warping, and cracking during Canadian temperature swings.

Fiber cement exhibits minimal thermal movement, expanding only 2mm per 12-foot section. This stability prevents gaps, maintains seal integrity, and reduces fastener stress. The dimensional stability particularly benefits homes experiencing rapid temperature changes.

Temperature Performance Comparison

Vinyl at -30°C: Becomes brittle, impact resistance drops 60%.

Fiber Cement at -30°C: Maintains flexibility and impact resistance.

Installation Temperature: Vinyl requires above 0°C, fiber cement installs year-round.

2. Moisture Management in Canadian Humidity

Canadian winters bring snow, ice, and humidity challenges. Vinyl's non-porous surface sheds water effectively but can trap moisture behind if improperly installed. Ice dams force water under vinyl edges, potentially causing hidden damage. Quality installation with proper vapor barriers prevents these issues.

Fiber cement absorbs minimal moisture (less than 5%) and releases it without damage. The material breathes better than vinyl, reducing condensation risks. However, cut edges need sealing to prevent moisture infiltration. Proper finishing protects fiber cement from freeze-thaw damage.

Winter Moisture Resistance

Ice Dam Performance: Fiber cement resists ice lifting better than vinyl.

Snow Load: Both handle snow weight, fiber cement shows no deformation.

Freeze-Thaw Cycles: Fiber cement superior, vinyl may crack if water trapped.

3. Impact Resistance in Freezing Temperatures

Cold makes vinyl brittle and prone to cracking from impacts. Hockey pucks, ice chunks, or ladder contact can shatter frozen vinyl. Insulated vinyl performs better but still becomes fragile below -20°C. Spring reveals winter impact damage when temperatures warm.

Fiber cement maintains impact resistance regardless of temperature. The material withstands hail, debris, and accidental impacts year-round. This durability proves valuable during ice storms common in Ontario and Quebec.

Real-World Impact Testing

Hail Resistance: Fiber cement survives golf-ball sized hail, vinyl may crack.

Wind-Blown Debris: Fiber cement unmarked, vinyl shows dents or breaks.

Ladder Marks: Fiber cement resists scratching, vinyl scars easily.

4. Installation and Labour Considerations

Vinyl installation costs less due to lighter weight and easier handling. Experienced DIYers can install vinyl, though professional installation ensures proper expansion gaps. Winter installation poses challenges as vinyl becomes difficult to cut cleanly when cold.

Fiber cement requires professional installation due to weight and specialized tools. Each board weighs 2-3 times more than vinyl. Installation costs run 30-40% higher than vinyl. However, fiber cement installs successfully in any temperature.

Installation Cost Breakdown

Vinyl Labour: $5-7 per square foot in Ontario.

Fiber Cement Labour: $8-12 per square foot in Ontario.

DIY Possibility: Vinyl feasible, fiber cement not recommended.

5. Long-Term Cost Analysis for Canadian Homes

Initial costs favor vinyl at $15-18 per square foot installed versus fiber cement's $20-25. However, fiber cement's 50-year lifespan versus vinyl's 25-year average changes the calculation. Factor in vinyl's higher maintenance needs and potential storm damage repairs.

Over 50 years, fiber cement often costs less despite higher upfront investment. Energy efficiency also factors in, with fiber cement providing better insulation value. Canadian homeowners save 10-15% on heating costs with fiber cement's superior thermal mass.

50-Year Total Cost Comparison

Vinyl Total: Two installations plus maintenance = $35,000-40,000.

Fiber Cement Total: One installation plus painting = $30,000-35,000.

Energy Savings: Fiber cement saves $200-400 annually on heating.

Expert Recommendations by Region

Coastal regions benefit from fiber cement's moisture resistance. Northern Ontario's extreme cold makes quality insulated vinyl viable. Southern Ontario's freeze-thaw cycles favor fiber cement's stability. Urban areas with higher property values justify fiber cement investment. Budget-conscious homeowners in stable climates find vinyl sufficient.

Consider your specific microclimate, budget, and long-term plans. Both materials protect Canadian homes effectively when properly installed. The choice depends on prioritizing upfront costs versus long-term value.

Conclusion

Fiber cement siding offers superior winter performance for Canadian homes, resisting freeze-thaw damage, maintaining stability, and providing 50-year durability. Vinyl siding delivers acceptable performance at lower initial cost, making it suitable for budget-conscious homeowners. Your choice depends on balancing upfront investment against long-term value and maintenance requirements.

At Custom Contracting, we install both vinyl and fiber cement siding with expertise gained from 25+ years serving Canadian homeowners. We'll assess your specific needs and recommend the optimal solution.

Call us at 289-212-6569 or fill out our convenient online form for your personalized consultation.

| Project Component | Average Cost | % of Total |

|---|---|---|

| Materials | $5,000 - $8,000 | 50-60% |

| Labor | $3,000 - $5,000 | 30-35% |

| Permits & Disposal | $500 - $1,000 | 5-10% |

| Total Project | $8,500 - $14,000 | 100% |

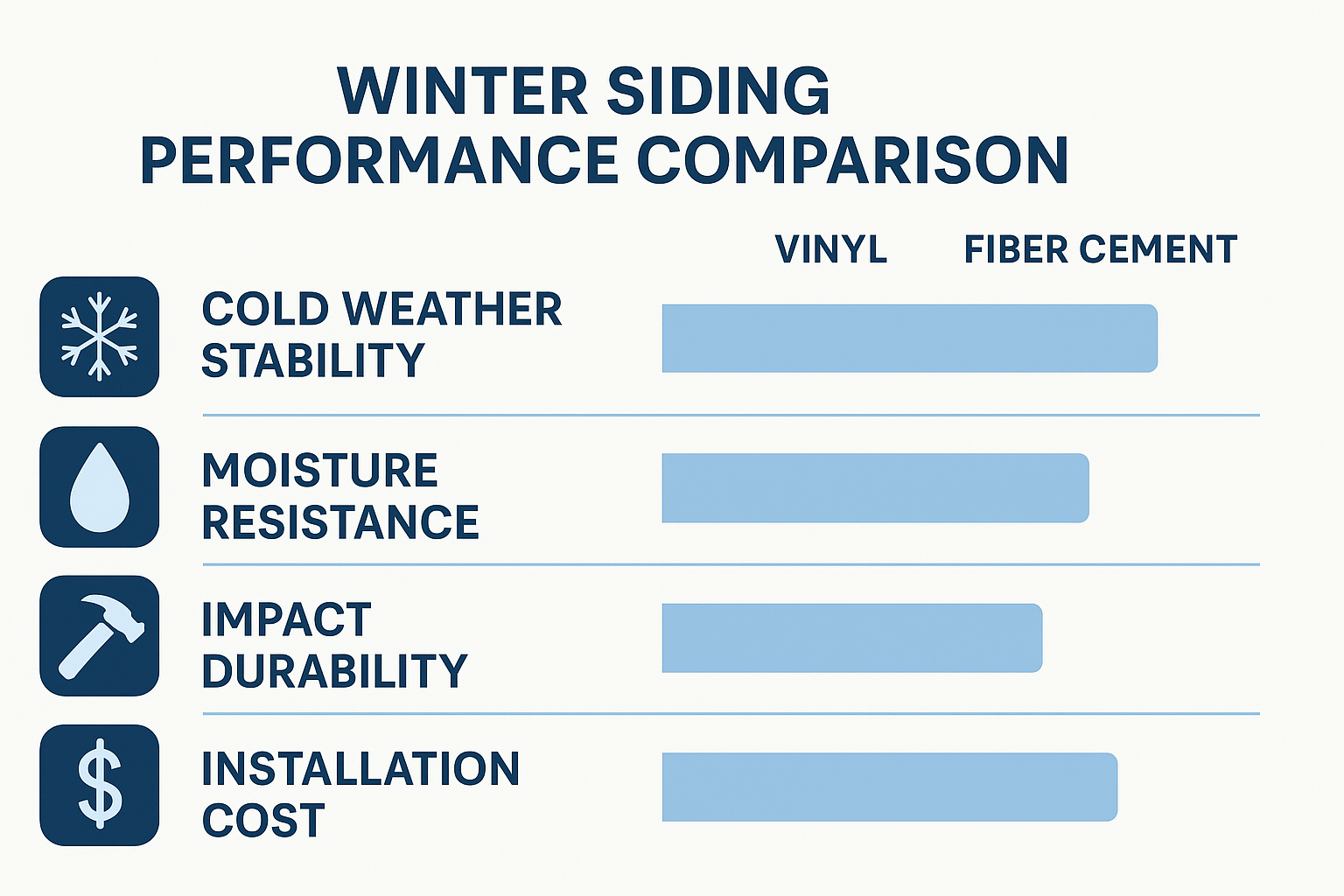

Vinyl vs. Fiber Cement: Canadian Winter Performance Analysis

Canadian winters test siding materials with temperature swings from -40°C to +5°C, sometimes within days. Ice formation, snow load, and freeze-thaw cycles challenge material integrity. Understanding how vinyl and fiber cement respond to these conditions guides your selection.

Quick comparison overview:

Vinyl Siding: Expands/contracts significantly, lower cost, easier installation.

Fiber Cement: Minimal movement, higher cost, professional installation required.

Durability Winner: Fiber cement lasts 50+ years vs vinyl's 20-30 years.

Cost Winner: Vinyl costs 40-50% less installed.

Maintenance Winner: Vinyl needs less frequent maintenance.

📊 Siding Material Comparison

Siding Type

Durability

Maintenance

Cost Range

Vinyl Siding

⭐⭐⭐⭐

Low

$3-$8/sq ft

Fiber Cement

⭐⭐⭐⭐⭐

Low-Medium

$6-$12/sq ft

Wood Siding

⭐⭐⭐

High

$8-$15/sq ft

Metal Siding

⭐⭐⭐⭐⭐

Very Low

$7-$16/sq ft

📊 Maintenance Schedule

Frequency

Task

Importance

Monthly

Visual inspection

Medium

Quarterly

Clean gutters & downspouts

High

Bi-Annually

Professional inspection

High

Annually

Deep cleaning & repairs

Medium

1. Cold Weather Expansion and Contraction Rates

Vinyl siding expands and contracts dramatically with temperature changes. A 12-foot vinyl panel can change length by 1.3cm between summer and winter extremes. This movement requires proper installation with expansion gaps. Improper installation causes buckling, warping, and cracking during Canadian temperature swings.

Fiber cement exhibits minimal thermal movement, expanding only 2mm per 12-foot section. This stability prevents gaps, maintains seal integrity, and reduces fastener stress. The dimensional stability particularly benefits homes experiencing rapid temperature changes.

Temperature Performance Comparison

Vinyl at -30°C: Becomes brittle, impact resistance drops 60%.

Fiber Cement at -30°C: Maintains flexibility and impact resistance.

Installation Temperature: Vinyl requires above 0°C, fiber cement installs year-round.

2. Moisture Management in Canadian Humidity

Canadian winters bring snow, ice, and humidity challenges. Vinyl's non-porous surface sheds water effectively but can trap moisture behind if improperly installed. Ice dams force water under vinyl edges, potentially causing hidden damage. Quality installation with proper vapor barriers prevents these issues.

Fiber cement absorbs minimal moisture (less than 5%) and releases it without damage. The material breathes better than vinyl, reducing condensation risks. However, cut edges need sealing to prevent moisture infiltration. Proper finishing protects fiber cement from freeze-thaw damage.

Winter Moisture Resistance

Ice Dam Performance: Fiber cement resists ice lifting better than vinyl.

Snow Load: Both handle snow weight, fiber cement shows no deformation.

Freeze-Thaw Cycles: Fiber cement superior, vinyl may crack if water trapped.

3. Impact Resistance in Freezing Temperatures

Cold makes vinyl brittle and prone to cracking from impacts. Hockey pucks, ice chunks, or ladder contact can shatter frozen vinyl. Insulated vinyl performs better but still becomes fragile below -20°C. Spring reveals winter impact damage when temperatures warm.

Fiber cement maintains impact resistance regardless of temperature. The material withstands hail, debris, and accidental impacts year-round. This durability proves valuable during ice storms common in Ontario and Quebec.

Real-World Impact Testing

Hail Resistance: Fiber cement survives golf-ball sized hail, vinyl may crack.

Wind-Blown Debris: Fiber cement unmarked, vinyl shows dents or breaks.

Ladder Marks: Fiber cement resists scratching, vinyl scars easily.

4. Installation and Labour Considerations

Vinyl installation costs less due to lighter weight and easier handling. Experienced DIYers can install vinyl, though professional installation ensures proper expansion gaps. Winter installation poses challenges as vinyl becomes difficult to cut cleanly when cold.

Fiber cement requires professional installation due to weight and specialized tools. Each board weighs 2-3 times more than vinyl. Installation costs run 30-40% higher than vinyl. However, fiber cement installs successfully in any temperature.

Installation Cost Breakdown

Vinyl Labour: $5-7 per square foot in Ontario.

Fiber Cement Labour: $8-12 per square foot in Ontario.

DIY Possibility: Vinyl feasible, fiber cement not recommended.

5. Long-Term Cost Analysis for Canadian Homes

Initial costs favor vinyl at $15-18 per square foot installed versus fiber cement's $20-25. However, fiber cement's 50-year lifespan versus vinyl's 25-year average changes the calculation. Factor in vinyl's higher maintenance needs and potential storm damage repairs.

Over 50 years, fiber cement often costs less despite higher upfront investment. Energy efficiency also factors in, with fiber cement providing better insulation value. Canadian homeowners save 10-15% on heating costs with fiber cement's superior thermal mass.

50-Year Total Cost Comparison

Vinyl Total: Two installations plus maintenance = $35,000-40,000.

Fiber Cement Total: One installation plus painting = $30,000-35,000.

Energy Savings: Fiber cement saves $200-400 annually on heating.

Expert Recommendations by Region

Coastal regions benefit from fiber cement's moisture resistance. Northern Ontario's extreme cold makes quality insulated vinyl viable. Southern Ontario's freeze-thaw cycles favor fiber cement's stability. Urban areas with higher property values justify fiber cement investment. Budget-conscious homeowners in stable climates find vinyl sufficient.

Consider your specific microclimate, budget, and long-term plans. Both materials protect Canadian homes effectively when properly installed. The choice depends on prioritizing upfront costs versus long-term value.

Conclusion

Fiber cement siding offers superior winter performance for Canadian homes, resisting freeze-thaw damage, maintaining stability, and providing 50-year durability. Vinyl siding delivers acceptable performance at lower initial cost, making it suitable for budget-conscious homeowners. Your choice depends on balancing upfront investment against long-term value and maintenance requirements.

At Custom Contracting, we install both vinyl and fiber cement siding with expertise gained from 25+ years serving Canadian homeowners. We'll assess your specific needs and recommend the optimal solution.

Call us at 289-212-6569 or fill out our convenient online form for your personalized consultation.

| Siding Type | Durability | Maintenance | Cost Range |

|---|---|---|---|

| Vinyl Siding | ⭐⭐⭐⭐ | Low | $3-$8/sq ft |

| Fiber Cement | ⭐⭐⭐⭐⭐ | Low-Medium | $6-$12/sq ft |

| Wood Siding | ⭐⭐⭐ | High | $8-$15/sq ft |

| Metal Siding | ⭐⭐⭐⭐⭐ | Very Low | $7-$16/sq ft |

📊 Maintenance Schedule

Frequency

Task

Importance

Monthly

Visual inspection

Medium

Quarterly

Clean gutters & downspouts

High

Bi-Annually

Professional inspection

High

Annually

Deep cleaning & repairs

Medium

1. Cold Weather Expansion and Contraction Rates

Vinyl siding expands and contracts dramatically with temperature changes. A 12-foot vinyl panel can change length by 1.3cm between summer and winter extremes. This movement requires proper installation with expansion gaps. Improper installation causes buckling, warping, and cracking during Canadian temperature swings.

Fiber cement exhibits minimal thermal movement, expanding only 2mm per 12-foot section. This stability prevents gaps, maintains seal integrity, and reduces fastener stress. The dimensional stability particularly benefits homes experiencing rapid temperature changes.

Temperature Performance Comparison

Vinyl at -30°C: Becomes brittle, impact resistance drops 60%.

Fiber Cement at -30°C: Maintains flexibility and impact resistance.

Installation Temperature: Vinyl requires above 0°C, fiber cement installs year-round.

2. Moisture Management in Canadian Humidity

Canadian winters bring snow, ice, and humidity challenges. Vinyl's non-porous surface sheds water effectively but can trap moisture behind if improperly installed. Ice dams force water under vinyl edges, potentially causing hidden damage. Quality installation with proper vapor barriers prevents these issues.

Fiber cement absorbs minimal moisture (less than 5%) and releases it without damage. The material breathes better than vinyl, reducing condensation risks. However, cut edges need sealing to prevent moisture infiltration. Proper finishing protects fiber cement from freeze-thaw damage.

Winter Moisture Resistance

Ice Dam Performance: Fiber cement resists ice lifting better than vinyl.

Snow Load: Both handle snow weight, fiber cement shows no deformation.

Freeze-Thaw Cycles: Fiber cement superior, vinyl may crack if water trapped.

3. Impact Resistance in Freezing Temperatures

Cold makes vinyl brittle and prone to cracking from impacts. Hockey pucks, ice chunks, or ladder contact can shatter frozen vinyl. Insulated vinyl performs better but still becomes fragile below -20°C. Spring reveals winter impact damage when temperatures warm.

Fiber cement maintains impact resistance regardless of temperature. The material withstands hail, debris, and accidental impacts year-round. This durability proves valuable during ice storms common in Ontario and Quebec.

Real-World Impact Testing

Hail Resistance: Fiber cement survives golf-ball sized hail, vinyl may crack.

Wind-Blown Debris: Fiber cement unmarked, vinyl shows dents or breaks.

Ladder Marks: Fiber cement resists scratching, vinyl scars easily.

4. Installation and Labour Considerations

Vinyl installation costs less due to lighter weight and easier handling. Experienced DIYers can install vinyl, though professional installation ensures proper expansion gaps. Winter installation poses challenges as vinyl becomes difficult to cut cleanly when cold.

Fiber cement requires professional installation due to weight and specialized tools. Each board weighs 2-3 times more than vinyl. Installation costs run 30-40% higher than vinyl. However, fiber cement installs successfully in any temperature.

Installation Cost Breakdown

Vinyl Labour: $5-7 per square foot in Ontario.

Fiber Cement Labour: $8-12 per square foot in Ontario.

DIY Possibility: Vinyl feasible, fiber cement not recommended.

5. Long-Term Cost Analysis for Canadian Homes

Initial costs favor vinyl at $15-18 per square foot installed versus fiber cement's $20-25. However, fiber cement's 50-year lifespan versus vinyl's 25-year average changes the calculation. Factor in vinyl's higher maintenance needs and potential storm damage repairs.

Over 50 years, fiber cement often costs less despite higher upfront investment. Energy efficiency also factors in, with fiber cement providing better insulation value. Canadian homeowners save 10-15% on heating costs with fiber cement's superior thermal mass.

50-Year Total Cost Comparison

Vinyl Total: Two installations plus maintenance = $35,000-40,000.

Fiber Cement Total: One installation plus painting = $30,000-35,000.

Energy Savings: Fiber cement saves $200-400 annually on heating.

Expert Recommendations by Region

Coastal regions benefit from fiber cement's moisture resistance. Northern Ontario's extreme cold makes quality insulated vinyl viable. Southern Ontario's freeze-thaw cycles favor fiber cement's stability. Urban areas with higher property values justify fiber cement investment. Budget-conscious homeowners in stable climates find vinyl sufficient.

Consider your specific microclimate, budget, and long-term plans. Both materials protect Canadian homes effectively when properly installed. The choice depends on prioritizing upfront costs versus long-term value.

Conclusion

Fiber cement siding offers superior winter performance for Canadian homes, resisting freeze-thaw damage, maintaining stability, and providing 50-year durability. Vinyl siding delivers acceptable performance at lower initial cost, making it suitable for budget-conscious homeowners. Your choice depends on balancing upfront investment against long-term value and maintenance requirements.

At Custom Contracting, we install both vinyl and fiber cement siding with expertise gained from 25+ years serving Canadian homeowners. We'll assess your specific needs and recommend the optimal solution.

Call us at 289-212-6569 or fill out our convenient online form for your personalized consultation.

| Frequency | Task | Importance |

|---|---|---|

| Monthly | Visual inspection | Medium |

| Quarterly | Clean gutters & downspouts | High |

| Bi-Annually | Professional inspection | High |

| Annually | Deep cleaning & repairs | Medium |

1. Cold Weather Expansion and Contraction Rates

Vinyl siding expands and contracts dramatically with temperature changes. A 12-foot vinyl panel can change length by 1.3cm between summer and winter extremes. This movement requires proper installation with expansion gaps. Improper installation causes buckling, warping, and cracking during Canadian temperature swings.

Fiber cement exhibits minimal thermal movement, expanding only 2mm per 12-foot section. This stability prevents gaps, maintains seal integrity, and reduces fastener stress. The dimensional stability particularly benefits homes experiencing rapid temperature changes.

Temperature Performance Comparison

Vinyl at -30°C: Becomes brittle, impact resistance drops 60%.

Fiber Cement at -30°C: Maintains flexibility and impact resistance.

Installation Temperature: Vinyl requires above 0°C, fiber cement installs year-round.

2. Moisture Management in Canadian Humidity

Canadian winters bring snow, ice, and humidity challenges. Vinyl's non-porous surface sheds water effectively but can trap moisture behind if improperly installed. Ice dams force water under vinyl edges, potentially causing hidden damage. Quality installation with proper vapor barriers prevents these issues.

Fiber cement absorbs minimal moisture (less than 5%) and releases it without damage. The material breathes better than vinyl, reducing condensation risks. However, cut edges need sealing to prevent moisture infiltration. Proper finishing protects fiber cement from freeze-thaw damage.

Winter Moisture Resistance

Ice Dam Performance: Fiber cement resists ice lifting better than vinyl.

Snow Load: Both handle snow weight, fiber cement shows no deformation.

Freeze-Thaw Cycles: Fiber cement superior, vinyl may crack if water trapped.

3. Impact Resistance in Freezing Temperatures

Cold makes vinyl brittle and prone to cracking from impacts. Hockey pucks, ice chunks, or ladder contact can shatter frozen vinyl. Insulated vinyl performs better but still becomes fragile below -20°C. Spring reveals winter impact damage when temperatures warm.

Fiber cement maintains impact resistance regardless of temperature. The material withstands hail, debris, and accidental impacts year-round. This durability proves valuable during ice storms common in Ontario and Quebec.

Real-World Impact Testing

Hail Resistance: Fiber cement survives golf-ball sized hail, vinyl may crack.

Wind-Blown Debris: Fiber cement unmarked, vinyl shows dents or breaks.

Ladder Marks: Fiber cement resists scratching, vinyl scars easily.

4. Installation and Labour Considerations

Vinyl installation costs less due to lighter weight and easier handling. Experienced DIYers can install vinyl, though professional installation ensures proper expansion gaps. Winter installation poses challenges as vinyl becomes difficult to cut cleanly when cold.

Fiber cement requires professional installation due to weight and specialized tools. Each board weighs 2-3 times more than vinyl. Installation costs run 30-40% higher than vinyl. However, fiber cement installs successfully in any temperature.

Installation Cost Breakdown

Vinyl Labour: $5-7 per square foot in Ontario.

Fiber Cement Labour: $8-12 per square foot in Ontario.

DIY Possibility: Vinyl feasible, fiber cement not recommended.

5. Long-Term Cost Analysis for Canadian Homes

Initial costs favor vinyl at $15-18 per square foot installed versus fiber cement's $20-25. However, fiber cement's 50-year lifespan versus vinyl's 25-year average changes the calculation. Factor in vinyl's higher maintenance needs and potential storm damage repairs.

Over 50 years, fiber cement often costs less despite higher upfront investment. Energy efficiency also factors in, with fiber cement providing better insulation value. Canadian homeowners save 10-15% on heating costs with fiber cement's superior thermal mass.

50-Year Total Cost Comparison

Vinyl Total: Two installations plus maintenance = $35,000-40,000.

Fiber Cement Total: One installation plus painting = $30,000-35,000.

Energy Savings: Fiber cement saves $200-400 annually on heating.

Expert Recommendations by Region

Coastal regions benefit from fiber cement's moisture resistance. Northern Ontario's extreme cold makes quality insulated vinyl viable. Southern Ontario's freeze-thaw cycles favor fiber cement's stability. Urban areas with higher property values justify fiber cement investment. Budget-conscious homeowners in stable climates find vinyl sufficient.

Consider your specific microclimate, budget, and long-term plans. Both materials protect Canadian homes effectively when properly installed. The choice depends on prioritizing upfront costs versus long-term value.

Conclusion

Fiber cement siding offers superior winter performance for Canadian homes, resisting freeze-thaw damage, maintaining stability, and providing 50-year durability. Vinyl siding delivers acceptable performance at lower initial cost, making it suitable for budget-conscious homeowners. Your choice depends on balancing upfront investment against long-term value and maintenance requirements.

At Custom Contracting, we install both vinyl and fiber cement siding with expertise gained from 25+ years serving Canadian homeowners. We'll assess your specific needs and recommend the optimal solution.

Call us at 289-212-6569 or fill out our convenient online form for your personalized consultation.

2. Moisture Management in Canadian Humidity

Canadian winters bring snow, ice, and humidity challenges. Vinyl's non-porous surface sheds water effectively but can trap moisture behind if improperly installed. Ice dams force water under vinyl edges, potentially causing hidden damage. Quality installation with proper vapor barriers prevents these issues.

Fiber cement absorbs minimal moisture (less than 5%) and releases it without damage. The material breathes better than vinyl, reducing condensation risks. However, cut edges need sealing to prevent moisture infiltration. Proper finishing protects fiber cement from freeze-thaw damage.

Winter Moisture Resistance

Ice Dam Performance: Fiber cement resists ice lifting better than vinyl.

Snow Load: Both handle snow weight, fiber cement shows no deformation.

Freeze-Thaw Cycles: Fiber cement superior, vinyl may crack if water trapped.

3. Impact Resistance in Freezing Temperatures

Cold makes vinyl brittle and prone to cracking from impacts. Hockey pucks, ice chunks, or ladder contact can shatter frozen vinyl. Insulated vinyl performs better but still becomes fragile below -20°C. Spring reveals winter impact damage when temperatures warm.

Fiber cement maintains impact resistance regardless of temperature. The material withstands hail, debris, and accidental impacts year-round. This durability proves valuable during ice storms common in Ontario and Quebec.

Real-World Impact Testing

Hail Resistance: Fiber cement survives golf-ball sized hail, vinyl may crack.

Wind-Blown Debris: Fiber cement unmarked, vinyl shows dents or breaks.

Ladder Marks: Fiber cement resists scratching, vinyl scars easily.

4. Installation and Labour Considerations

Vinyl installation costs less due to lighter weight and easier handling. Experienced DIYers can install vinyl, though professional installation ensures proper expansion gaps. Winter installation poses challenges as vinyl becomes difficult to cut cleanly when cold.

Fiber cement requires professional installation due to weight and specialized tools. Each board weighs 2-3 times more than vinyl. Installation costs run 30-40% higher than vinyl. However, fiber cement installs successfully in any temperature.

Installation Cost Breakdown

Vinyl Labour: $5-7 per square foot in Ontario.

Fiber Cement Labour: $8-12 per square foot in Ontario.

DIY Possibility: Vinyl feasible, fiber cement not recommended.

5. Long-Term Cost Analysis for Canadian Homes

Initial costs favor vinyl at $15-18 per square foot installed versus fiber cement's $20-25. However, fiber cement's 50-year lifespan versus vinyl's 25-year average changes the calculation. Factor in vinyl's higher maintenance needs and potential storm damage repairs.

Over 50 years, fiber cement often costs less despite higher upfront investment. Energy efficiency also factors in, with fiber cement providing better insulation value. Canadian homeowners save 10-15% on heating costs with fiber cement's superior thermal mass.

50-Year Total Cost Comparison

Vinyl Total: Two installations plus maintenance = $35,000-40,000.

Fiber Cement Total: One installation plus painting = $30,000-35,000.

Energy Savings: Fiber cement saves $200-400 annually on heating.

Expert Recommendations by Region

Coastal regions benefit from fiber cement's moisture resistance. Northern Ontario's extreme cold makes quality insulated vinyl viable. Southern Ontario's freeze-thaw cycles favor fiber cement's stability. Urban areas with higher property values justify fiber cement investment. Budget-conscious homeowners in stable climates find vinyl sufficient.

Consider your specific microclimate, budget, and long-term plans. Both materials protect Canadian homes effectively when properly installed. The choice depends on prioritizing upfront costs versus long-term value.

Conclusion

Fiber cement siding offers superior winter performance for Canadian homes, resisting freeze-thaw damage, maintaining stability, and providing 50-year durability. Vinyl siding delivers acceptable performance at lower initial cost, making it suitable for budget-conscious homeowners. Your choice depends on balancing upfront investment against long-term value and maintenance requirements.

At Custom Contracting, we install both vinyl and fiber cement siding with expertise gained from 25+ years serving Canadian homeowners. We'll assess your specific needs and recommend the optimal solution.

Call us at 289-212-6569 or fill out our convenient online form for your personalized consultation.

3. Impact Resistance in Freezing Temperatures

Cold makes vinyl brittle and prone to cracking from impacts. Hockey pucks, ice chunks, or ladder contact can shatter frozen vinyl. Insulated vinyl performs better but still becomes fragile below -20°C. Spring reveals winter impact damage when temperatures warm.

Fiber cement maintains impact resistance regardless of temperature. The material withstands hail, debris, and accidental impacts year-round. This durability proves valuable during ice storms common in Ontario and Quebec.

Real-World Impact Testing

Hail Resistance: Fiber cement survives golf-ball sized hail, vinyl may crack.

Wind-Blown Debris: Fiber cement unmarked, vinyl shows dents or breaks.

Ladder Marks: Fiber cement resists scratching, vinyl scars easily.

4. Installation and Labour Considerations

Vinyl installation costs less due to lighter weight and easier handling. Experienced DIYers can install vinyl, though professional installation ensures proper expansion gaps. Winter installation poses challenges as vinyl becomes difficult to cut cleanly when cold.

Fiber cement requires professional installation due to weight and specialized tools. Each board weighs 2-3 times more than vinyl. Installation costs run 30-40% higher than vinyl. However, fiber cement installs successfully in any temperature.

Installation Cost Breakdown

Vinyl Labour: $5-7 per square foot in Ontario.

Fiber Cement Labour: $8-12 per square foot in Ontario.

DIY Possibility: Vinyl feasible, fiber cement not recommended.

5. Long-Term Cost Analysis for Canadian Homes

Initial costs favor vinyl at $15-18 per square foot installed versus fiber cement's $20-25. However, fiber cement's 50-year lifespan versus vinyl's 25-year average changes the calculation. Factor in vinyl's higher maintenance needs and potential storm damage repairs.

Over 50 years, fiber cement often costs less despite higher upfront investment. Energy efficiency also factors in, with fiber cement providing better insulation value. Canadian homeowners save 10-15% on heating costs with fiber cement's superior thermal mass.

50-Year Total Cost Comparison

Vinyl Total: Two installations plus maintenance = $35,000-40,000.

Fiber Cement Total: One installation plus painting = $30,000-35,000.

Energy Savings: Fiber cement saves $200-400 annually on heating.

Expert Recommendations by Region

Coastal regions benefit from fiber cement's moisture resistance. Northern Ontario's extreme cold makes quality insulated vinyl viable. Southern Ontario's freeze-thaw cycles favor fiber cement's stability. Urban areas with higher property values justify fiber cement investment. Budget-conscious homeowners in stable climates find vinyl sufficient.

Consider your specific microclimate, budget, and long-term plans. Both materials protect Canadian homes effectively when properly installed. The choice depends on prioritizing upfront costs versus long-term value.

Conclusion

Fiber cement siding offers superior winter performance for Canadian homes, resisting freeze-thaw damage, maintaining stability, and providing 50-year durability. Vinyl siding delivers acceptable performance at lower initial cost, making it suitable for budget-conscious homeowners. Your choice depends on balancing upfront investment against long-term value and maintenance requirements.

At Custom Contracting, we install both vinyl and fiber cement siding with expertise gained from 25+ years serving Canadian homeowners. We'll assess your specific needs and recommend the optimal solution.

Call us at 289-212-6569 or fill out our convenient online form for your personalized consultation.

4. Installation and Labour Considerations

Vinyl installation costs less due to lighter weight and easier handling. Experienced DIYers can install vinyl, though professional installation ensures proper expansion gaps. Winter installation poses challenges as vinyl becomes difficult to cut cleanly when cold.

Fiber cement requires professional installation due to weight and specialized tools. Each board weighs 2-3 times more than vinyl. Installation costs run 30-40% higher than vinyl. However, fiber cement installs successfully in any temperature.

Installation Cost Breakdown

Vinyl Labour: $5-7 per square foot in Ontario.

Fiber Cement Labour: $8-12 per square foot in Ontario.

DIY Possibility: Vinyl feasible, fiber cement not recommended.

5. Long-Term Cost Analysis for Canadian Homes

Initial costs favor vinyl at $15-18 per square foot installed versus fiber cement's $20-25. However, fiber cement's 50-year lifespan versus vinyl's 25-year average changes the calculation. Factor in vinyl's higher maintenance needs and potential storm damage repairs.

Over 50 years, fiber cement often costs less despite higher upfront investment. Energy efficiency also factors in, with fiber cement providing better insulation value. Canadian homeowners save 10-15% on heating costs with fiber cement's superior thermal mass.

50-Year Total Cost Comparison

Vinyl Total: Two installations plus maintenance = $35,000-40,000.

Fiber Cement Total: One installation plus painting = $30,000-35,000.

Energy Savings: Fiber cement saves $200-400 annually on heating.

Expert Recommendations by Region

Coastal regions benefit from fiber cement's moisture resistance. Northern Ontario's extreme cold makes quality insulated vinyl viable. Southern Ontario's freeze-thaw cycles favor fiber cement's stability. Urban areas with higher property values justify fiber cement investment. Budget-conscious homeowners in stable climates find vinyl sufficient.

Consider your specific microclimate, budget, and long-term plans. Both materials protect Canadian homes effectively when properly installed. The choice depends on prioritizing upfront costs versus long-term value.

Conclusion

Fiber cement siding offers superior winter performance for Canadian homes, resisting freeze-thaw damage, maintaining stability, and providing 50-year durability. Vinyl siding delivers acceptable performance at lower initial cost, making it suitable for budget-conscious homeowners. Your choice depends on balancing upfront investment against long-term value and maintenance requirements.

At Custom Contracting, we install both vinyl and fiber cement siding with expertise gained from 25+ years serving Canadian homeowners. We'll assess your specific needs and recommend the optimal solution.

Call us at 289-212-6569 or fill out our convenient online form for your personalized consultation.

5. Long-Term Cost Analysis for Canadian Homes

Initial costs favor vinyl at $15-18 per square foot installed versus fiber cement's $20-25. However, fiber cement's 50-year lifespan versus vinyl's 25-year average changes the calculation. Factor in vinyl's higher maintenance needs and potential storm damage repairs.

Over 50 years, fiber cement often costs less despite higher upfront investment. Energy efficiency also factors in, with fiber cement providing better insulation value. Canadian homeowners save 10-15% on heating costs with fiber cement's superior thermal mass.

50-Year Total Cost Comparison

Vinyl Total: Two installations plus maintenance = $35,000-40,000.

Fiber Cement Total: One installation plus painting = $30,000-35,000.

Energy Savings: Fiber cement saves $200-400 annually on heating.

Expert Recommendations by Region

Coastal regions benefit from fiber cement's moisture resistance. Northern Ontario's extreme cold makes quality insulated vinyl viable. Southern Ontario's freeze-thaw cycles favor fiber cement's stability. Urban areas with higher property values justify fiber cement investment. Budget-conscious homeowners in stable climates find vinyl sufficient.

Consider your specific microclimate, budget, and long-term plans. Both materials protect Canadian homes effectively when properly installed. The choice depends on prioritizing upfront costs versus long-term value.

Conclusion

Fiber cement siding offers superior winter performance for Canadian homes, resisting freeze-thaw damage, maintaining stability, and providing 50-year durability. Vinyl siding delivers acceptable performance at lower initial cost, making it suitable for budget-conscious homeowners. Your choice depends on balancing upfront investment against long-term value and maintenance requirements.

At Custom Contracting, we install both vinyl and fiber cement siding with expertise gained from 25+ years serving Canadian homeowners. We'll assess your specific needs and recommend the optimal solution.

Call us at 289-212-6569 or fill out our convenient online form for your personalized consultation.